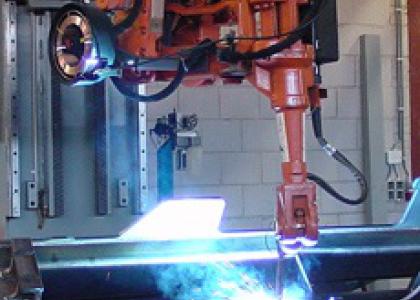

Welding Robotic System

Ship Manufacturing

TechComp, Inc. replaced an inoperable conveyor control system with a highly reliable PLC Controlled system for managing staged movements of the various very large steel components on sections and platforms. Sections are up to 30 meters long, weigh up to 4000 lbs., and stop within a 10-millimeter tolerance. Two eight axis robots perform welding operations based on uploaded CAD files. The operator control panel contains touchscreen HMIs and manual controls for operator interface. The main controls panel containing the VFDs and PLC controls also has a maintenance workstation where personnel can troubleshoot and or operate the line as needed. Four (4) pan/zoom/tilt cameras, integrated into the HMI, allow operator to view any part of the line without leaving the control panel.

Technology

- Rockwell Automation FactoryTalk View SE

- Rockwell Automation1756 ControLogix Processors

- Rockwell Automation 6181 & 6177 Workstations and Monitors

- Rockwell PowerFlex 755 Frequency Drives